Thermal Press Molding

SEG uses thermal press molding , also known as High Temperature Compression Molding for rapid production for a variety of small carbon parts like paddle blades. High Temperature Bismaleimide Composites manufacturing is used for high temperature and high impact applications.

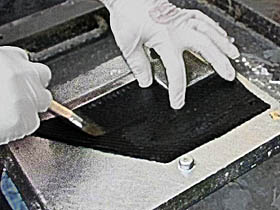

The typical thermal compression process includes both prepreg or manually saturated fabric placed into a 2-part (male and female) mold that is pre-charged and heated. When the mold is closed and placed under pressure, the material is compacted and cured by pressure and heat.

Compression molding offers excellent detail in geometric shapes, ranging from pattern and relief detailing, to complex curves and forms. Due to the short curing times, Thermal Press Molding offers the ability to rapidly create precision engineered composite parts.